Oxy Fuel Technology

Combustion of pure oxygen instead of fuel/air mixtures remove nitrogen, inert for combustion purposes, but active in transporting heat, offering several advantages:

– It reduces the exhaust gas volume of about 75% thus greatly lowering heat loss.

– It allows to drastically reduce the NOx emissions

– Less engineering work, as pipelines require smaller sections. Heat exchangers are no more necessary too.

– Increased productivity thanks to higher flame temperature and heat transfer ratio, and colder flue gas.

– Easier mixing with fuel, leading to more stable flames, as you have no more problems of air excess or deficit

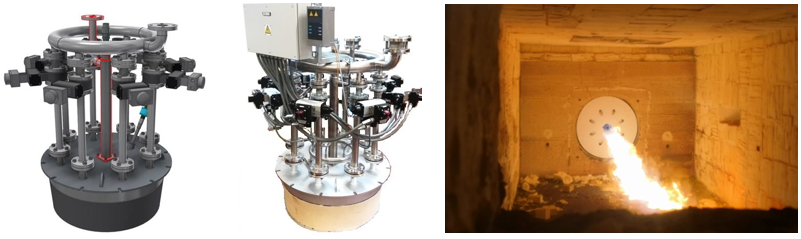

ESA, along with its strong collaboration with the SIAD Group has cumulated a huge experience in combustion of oxygen or enriched mixes and offer today standard or fully customised and complete solutions :

“STANDARD” OXY FUEL BURNERS UP TO 5MW:

|

- HT – High Turbulence (E3710) burners family

|

- AGO-NxT – Air-Gas-Oxygen (E3700). Air and / or oxygen burner, ideal for minimizing oxygen consumption when not required by the process, or even as a back up in case of problems in the oxygen supply itself.

|

- FT – Flame Turning Burner (Bulletin in preparation): allows to direct the flame, improving the homogeneity of the temperatures in the combustion chamber, or to concentrate the heat in particular points, for example towards a load of cold ingots in a aluminum holding/melting furnace

ON-DEMAND OXY FUEL BURNERS UP TO 21 MW (OR MORE)

|

Many other burner typologies can be developed and manufactured on purpose,

OXY FUEL SKIDS COMPLIANT TO PED AND EN 746

|